EasyBender G6

Products

Video

Hardware Features

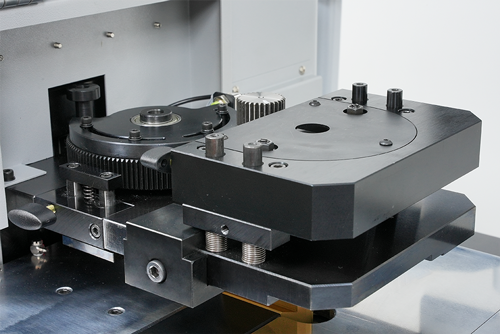

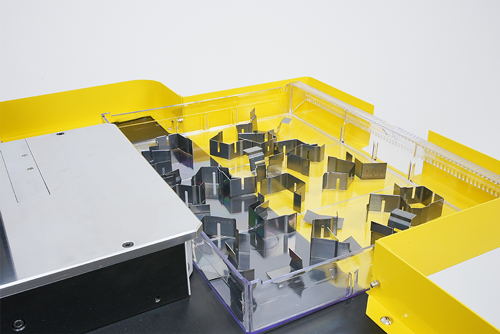

Completely redesigned bending module and nozzle

The bending module and nozzle have been redesigned for increased performance and quicker change over.

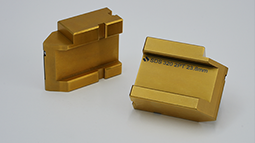

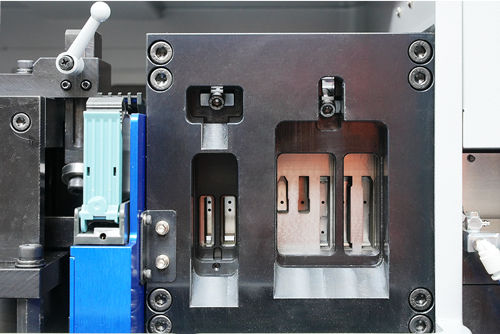

Newly designed powerful Post-Cut unit

The Post-Cut unit is capable of processing 2, 3 & 4pt cutting rule. Diemakers can choose either Cut-First – Bend Last or Bend First Cut Last options.

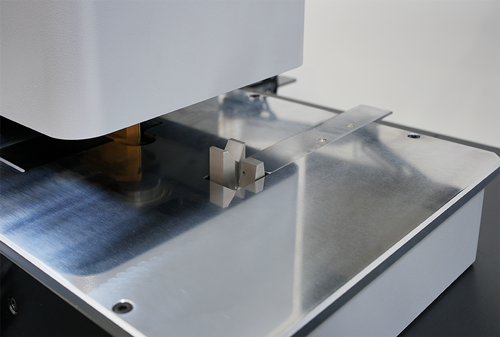

Collection Tray

The air jet nozzle moves the completed pieces whenever they are finished moving them into the tray.

Fully automatic height-adjustable tool module

The fully automatic height-adjustable End Cut tool module is standard on the EasyBender G6.

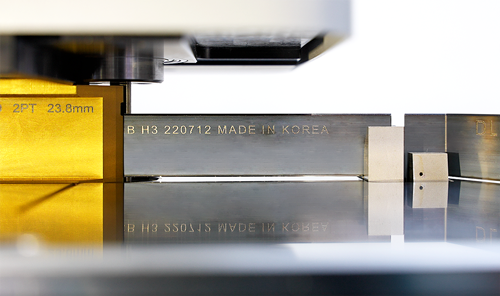

Inkjet marking unit

Segment labeling which allows users to readily identify processed rule segments.

Software Features

Brand-New Operating Software, EasyBender

Our Brand-New operating software, named EasyBender, is now provides a seamless user experience with intuitive and ease-of-use graphical interfaces.

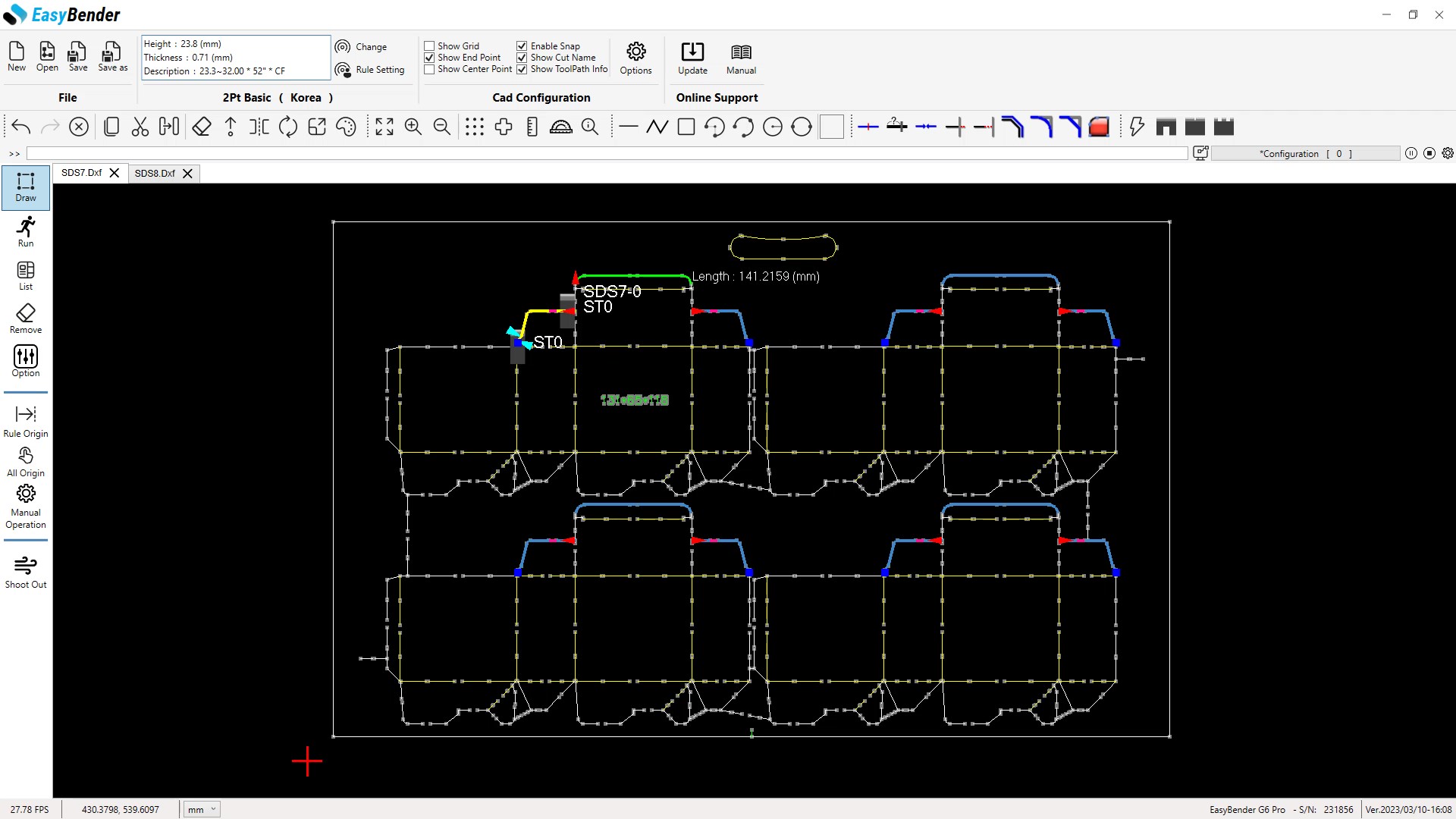

Same Pattern Auto Sorting

EasyBender automatically recognizes all the same shapes in the working file. No longer do you have to count the number of pieces required to complete your steel rule cutting die.

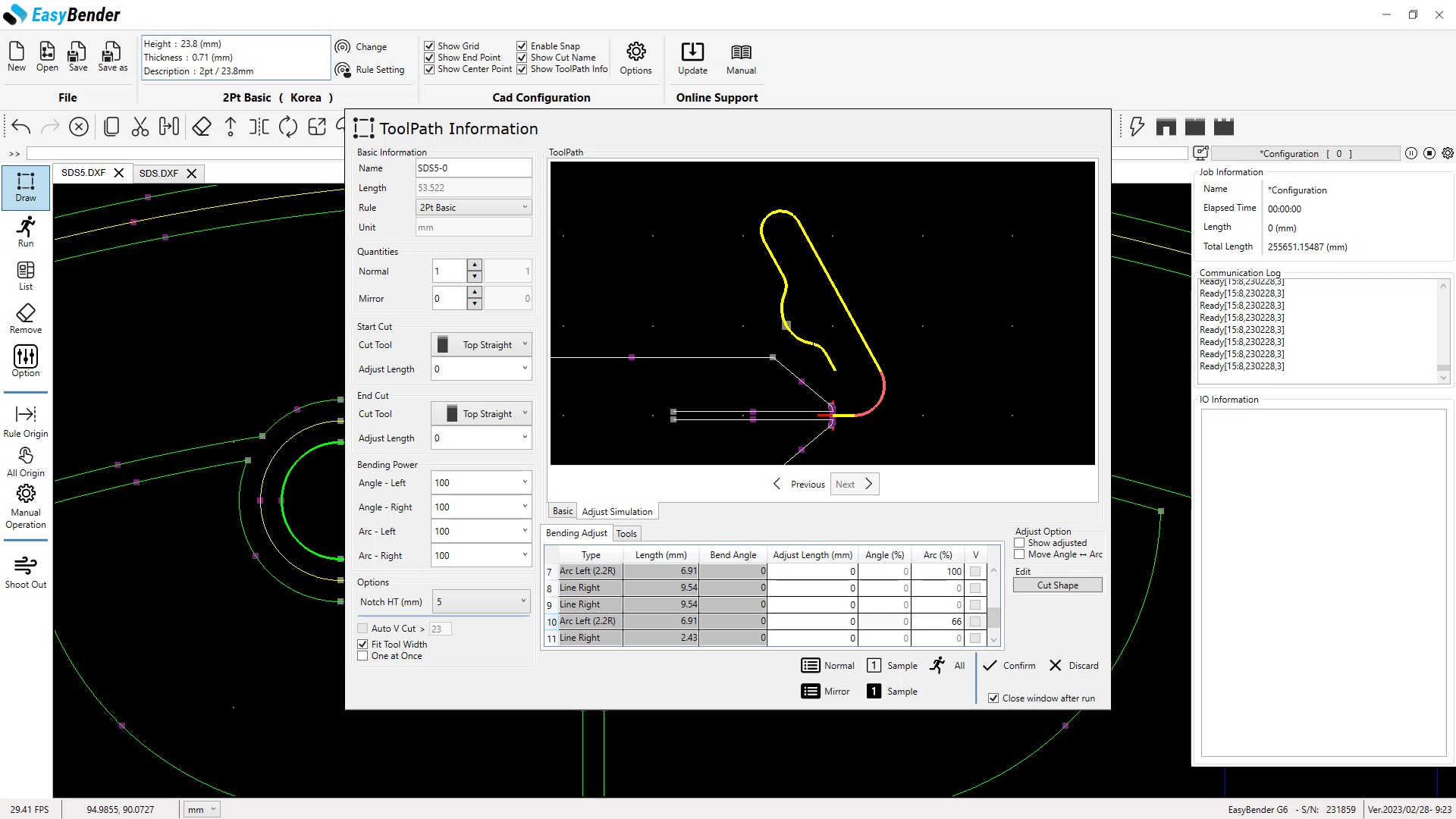

Bending Simulation & Adjustment

Virtually bend the plotted rule segment in advance to actually processing any steel rule segment.

User-Friendly HELPER functions

EasyBender provides HELPER functions that allow any user to easily calibrate and adjust all the machine parameters.

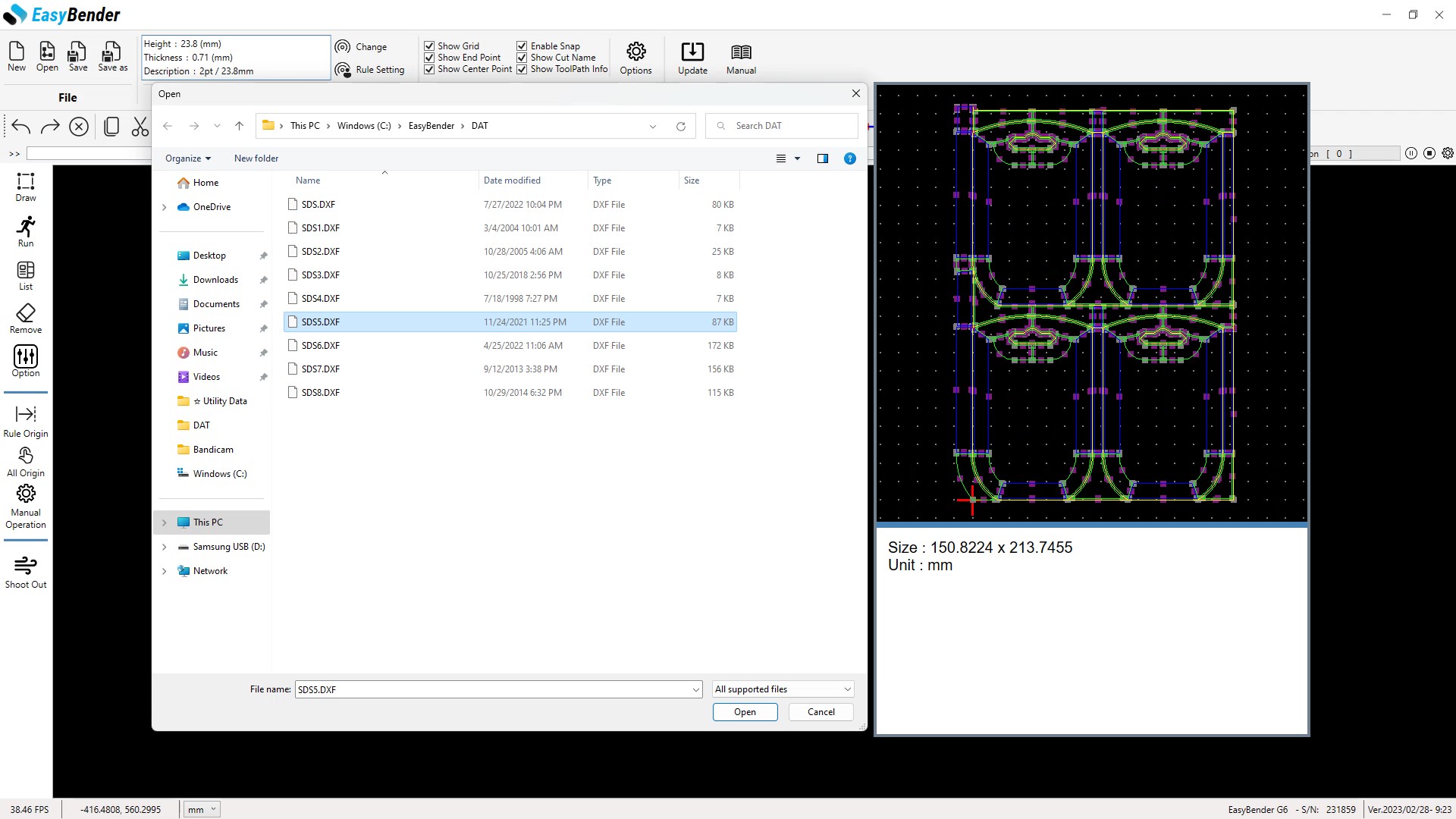

Preview Window

Users can now confirm they are choosing the correct file before opening it with the preview window. Even users can check the preview of files in other EasyBenders that are connected to the network system.

Online Updates

EasyBender provides online updates with a click of the mouse. With an internet connection, users can easily get the latest S/W and firmware updates.

Online Manuals and Remote Support

EasyBender provides comprehensive online manuals for quick troubleshooting. Users can also get the remote support service from us when their bender has any problem.

Networking Organization System

Users can utilize the networking organization system to increase your production capabilities. Connect multiple EasyBender series machines in a loop and assign a different process to each EasyBender with ease.

Specification

| Rule | Height | 23.3mm - 31.75mm | ||

|---|---|---|---|---|

| Thickness | 2pt, 3pt, 4pt | |||

| Cutting | ||||

| Notching | 2 Custom sizes | |||

| Minimum width | 2pt: 1.6mm / 3pt: 3.0mm / 4pt: 6.0mm | |||

| Maximum width | 7.0mm (Wider notches will double punch) | |||

| Height adjustable with shims | 12mm - 21mm | |||

| End Cut | End Miter, Start Miter, Straight, Straight Top, Top Miter | |||

| Fully automatic height adjustable | ||||

| Bending | Rule thickness | 2pt | 3pt | 4pt |

| Maximum angle | 125° | 120° | 115° | |

| Smallest radius that can be bent 180° | 3.2mm | 3.8mm | 5mm | |

| Shortest distance from start to a sharp bend | 2mm | 3mm | 4mm | |

| Shortest distance from end to a sharp bend | 4mm | 8mm | 10mm | |

| Post-Cutting | Available on all rule thickness including 4pt with any bevel type | |||

| Cut First - Bend Last / Bend First - Cut Last | ||||

| Inkjet Marking | (Optional) | |||

| Size (W x D x H) |

System without a tray | 1,320mm x 910mm x 1,700mm | ||

| System with a tray | 1,385mm x 910mm x 1,700mm | |||

| Coil Cassette | 680mm x 675mm x 1,150mm | |||

| Weight | Operating Weight | 400kg | ||

| Shipping Weight | 560kg | |||

| Power | Voltage | 220VAC, 15A, 50/60Hz, 1P | ||

| Max Peak Current | 13A, 3kW | |||

| Average Current | 4A, 920W | |||

| Air Pressure | Max Pressure | 0.9MPa (9kg/cm2) | ||

| Operating Range (typical) | 0.5 - 0.6MPa (4.5-5.5kg/cm2) | |||

| Environment | Temperature | 10 - 35℃ | ||

| Humidity | 10 - 80% | |||